Understanding the Starter Motor in Commercial Vehicles

A starter motor is a crucial component in commercial vehicles, playing a vital role in starting the engine’s operation. Unlike personal vehicles, commercial vehicles often operate under heavier loads and different conditions, making the efficiency and reliability of the starter motor even more critical. In this blog, we’ll explore the basics of a starter motor, how it works, its types, common issues, and maintenance tips used for commercial vehicles.

What is a Starter Motor (Self) and How does it work?

The starter motor is an electric device that starts the engine’s operation by turning the crankshaft. Once the engine starts running, the starter motor disengages, allowing the engine to move its own motion. In commercial vehicles, the starter motor is built to handle frequent usage, especially in heavy-duty applications such as trucks, buses, and construction equipment.The operation of a starter motor can be broken into the following steps:

- Ignition Starts: Turning the ignition key or pressing the start button sends an electrical signal to the solenoid.

- Gear Engagement: The solenoid moves the pinion gear to engage with the engine’s flywheel.

- Cranking: The starter motor rotates the flywheel, which in turn rotates the crankshaft, enabling the engine to start.

- Disengagement: Once the engine fires up, the pinion gear retracts, and the motor stops working to avoid damage.

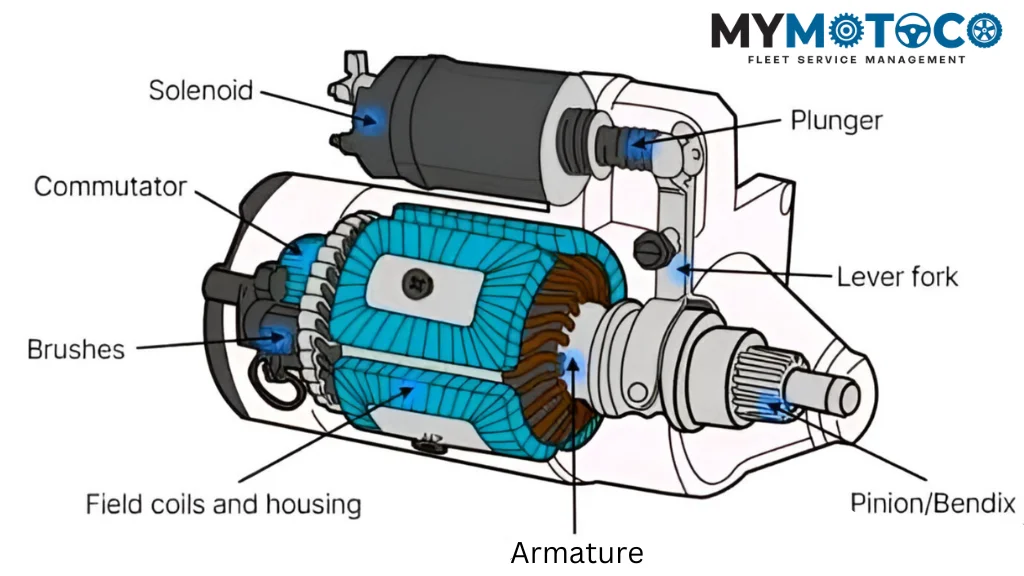

Components of a Starter Motor

- Armature: A core cylindrical part that rotates when electrical energy is supplied.

- Solenoid: Acts as an electrical relay, engaging and disengaging the motor’s drive system.

- Pinion Gear: A small gear that meshes with the flywheel to crank the engine.

- Flywheel: Connected to the engine, it transmits the rotation initiated by the starter motor.

- Field Coils or Magnets: Generate a magnetic field to drive the motor.

- Commutator and Brushes: Conduct electricity between stationary and moving parts of the motor.

- Drive Mechanism: Controls the engagement of the pinion gear with the flywheel.

Why Starter Motors are Crucial for Commercial Vehicles

- High Torque Requirements: Commercial vehicles have larger engines that need greater force to start.

- Frequent Usage: These vehicles are often turned on and off multiple times during the day, requiring a robust and durable starter motor.

- Harsh Operating Conditions: They perform reliably in extreme weather, heavy loads, and long usage.

Common Starter Motor Issues in Commercial Vehicles

- Slow Cranking: Often caused by a weak battery, poor electrical connections, or a failing motor.

- No Crank: Indicates issues with the solenoid, wiring, or a completely dead motor.

- Grinding Noise: Suggests problems with the pinion gear or flywheel teeth.

- Intermittent Operation: Could stem from faulty wiring, a weak connection, or a worn-out solenoid.

Maintenance Tips for Commercial Vehicle Starter Motors

- Regular Battery Checks: Ensure the battery is fully charged and terminals are clean to avoid electrical issues.

- Clean the Starter Motor: Remove dirt to prevent overheating.

- Lubrication: Timely lubricate the moving components for smooth operation.

- Timely Replacement: Replace the starter motor at the first sign of regular trouble to avoid breakdowns.

Importance of Choosing the Right Starter Motor

For commercial vehicles, the starter motor must face heavy use and challenging environments. Always choose high-quality, durable starter motors designed for the specific make and model of the vehicle. Look for trusted brands and suppliers to ensure long-term reliability.

Conclusion

The starter motor is an important component that ensures the safe operation of commercial vehicles. Regular maintenance, timely check for issues, and choosing the right motor are essential for good performance.

At MyMotoCo, we understand the importance of keeping your fleet running efficiently. Explore our wide selection of starter motors and other automotive components to ensure your commercial vehicles are always road-ready.